Sustainability - Occupational Safety and Health

The Meiden Group develops the “President’s Safety and Health Policy” and the “President’s Health & Productivity Management Policy” every year, and rolls out occupational safety and health and health management activities based on them. The President’s policies form a comprehensive code of conduct. They cover all employees (including part-time and temporary employees) of Meidensha and Meiden Group subsidiaries in Japan and abroad as well as employees of our partner companies.

We have explicitly stated that ensuring the health and safety of each employee is at the core of corporate management, and we work to eliminate industrial accidents and maintain and improve health.

“Safety comes first before anything else” and “Nothing is more valuable than good health”

At the Meiden Group, employee health and safety are core management values. We work to “ensure a safe environment that is conducive to work, as well as achieve comfort and affluence for employees,” as it says in the Meiden Group Corporate Code of Conduct and aim to be a leading health and safety company with zero industrial accidents.

Everyone in the Meiden Group shares the opinion that “Nothing is more valuable than good health” and supports the three pillars of physical health, mental health, and occupational health. With the company and the employees operating as one unit, we enact strategic health promotion campaigns that aim for continuous corporate growth and help employees to maintain healthy bodies and minds.

As the agents of Meidensha Group’s continuous growth, our employees recognize their role in maintaining their own mental and physical health and so they have enacted the following operating guidelines. The company actively supports employees building healthy minds and bodies.

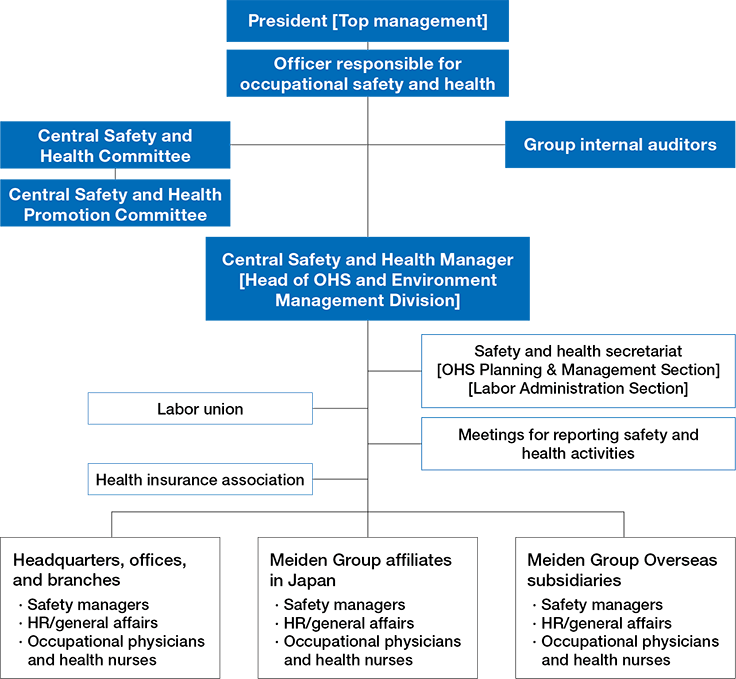

In Japan, we comply with laws and regulations, hold monthly meetings of the Safety and Health Committee at each site, where we encourage participation by unions and employees, and conduct consultation and information sharing relating to matters such as causes of and responses to industrial accidents, the status of employees that have taken leave due to illness, and other matters that require attention. Also, the Central Safety and Health Committee, chaired by the officer responsible for occupational safety and health as appointed by the President, discusses and makes decisions on matters relating to Group-wide policies and targets.

Not applicable: MEIDEN ENGINEERING CORPORATION, MEIDEN FACILITY SERVICE CORPORATION (and other than Numazu, Ota and Nagoya Management Center), MEIDEN CHEMICAL CO., LTD., EAML Engineering CO., LTD.

In FY2015, the Meiden Group obtained OHSAS 18001 certification for each of the four main Japanese production sites, Numazu Works, Ota Works, Nagoya Works, and Kofu Meidensha Electric Mfg. Co., Ltd., including on-site affiliates. Furthermore, MEIDEN SINGAPORE PTE. LTD. obtained certification in FY2013, and the four remaining main overseas sites, MEIDEN ZHENGZHOU ELECTRIC CO., LTD., SHANGHAI MEIDENSHA CHANGCHENG SWITCHGEAR CO., LTD., P.T. MEIDEN ENGINEERING INDONESIA, and MEIDEN T&D (INDIA) LIMITED, obtained certification in FY2017.

Since FY2018, we have promoted penetration of the Occupational Safety and Health Management System to the entire Group, as well as transition to and expanded application of ISO 45001 certification due to the need for international standards.

In FY2019, we acquired joint certification for the four main Japanese production sites (Ota Works, Numazu Works, Nagoya Works, and Kofu Meidensha Electric Mfg. Co., Ltd. *including on-site affiliates) under ISO 45001. In FY2020, we expanded ISO 45001 certification to Japanese workplaces other than production sites (Tokyo office, branches) and construction business units (Plant Construction Headquarters).

In FY2021, we plan to acquire certification for four Japanese affiliates. (MEIDEN PLANT SYSTEMS CORPORATION, MEIDEN AQUA BUSINESS COMPANY, M WINDS CO., LTD., and MEIDEN NANOPROCESS INNOVATIONS, INC.)

Going forward, we will continue to maintain and improve our occupational safety and health management system at all Meiden Group locations.

The Meiden Group conducts risk assessments to ensure a work environment where employees can work in health and safety.

We have established and are using rules and systems to manage not only workplaces that require measurement of the work environment and workplaces where chemicals must be managed, but also workplaces engaged in light tasks and office work. We use common risk assessment standards within the Group and are systematically taking steps to eliminate and reduce risks.

We also strive to identify sources of danger from past cases of industrial accidents and day-to-day near-miss initiatives, where our goal is to get participation by all employees. Once the dangers are identified, we visualize the health and safety risks in every workplace and tie them in with risk assessments. Then we take preliminary measures and work to improve the workplace environment.

The Meiden Group established the preliminary risk assessment system to provide information that benefits management decision-making. When screening business investments, a preliminary risk assessment meeting carefully examines investments that may have a significant impact on the Meiden Group. The system follows our Basic Policy regarding Establishment of a System to Ensure the Appropriateness of Business Activities.

During the assessment, we evaluate financial risks, responsibilities (such as product guarantees), and feasibility (such as systems). The Corporate Policy Planning Group and the Internal Control Promotion Division serve as the secretariat for preliminary risk assessment meetings, and their supervising officers determine whether a meeting needs to be held. Other units involved include the General and Legal Affairs Division, the Accounting and Financing Group, and the Sales Planning & Administration Group.

During M&A, a third-party unit performs the due diligence. Besides doing a financial investigation of the target company, we also evaluate it from an ESG perspective to strengthen risk management. This includes the target’s corporate culture, legal compliance systems including human rights concerns, compliance with environmental regulations, labor conditions, occupational safety and health, and other factors.

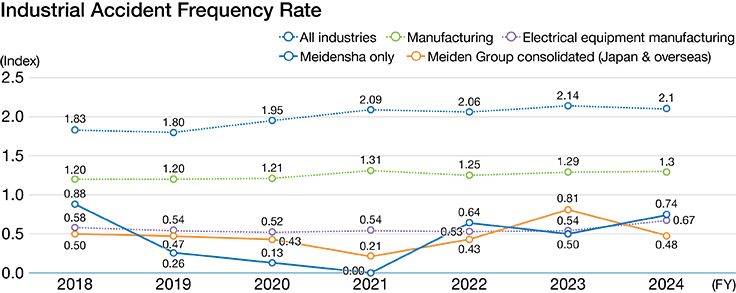

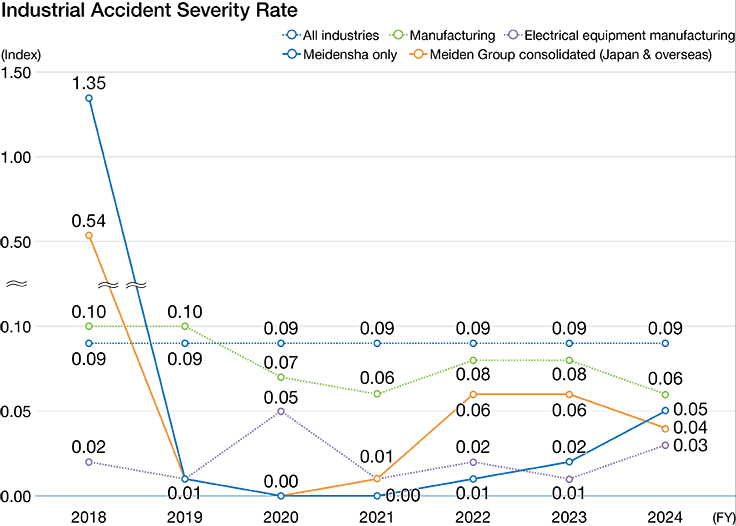

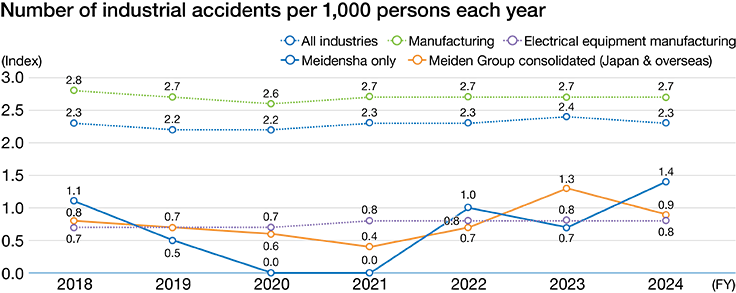

Safety Record (only Meidensha)

The Meiden Group has experienced industrial accidents throughout its long history and takes various measures to eliminate them. Measures include safety training, KYK (hazard prediction), risk assessment, safety patrols, a health and safety management system, and hands-on safety training.

The Meiden Group continues to actively conduct safety patrols, which is a long-standing practice. For these, we depend on not only our own eyes, but also bring in health and safety consultants to provide an outside perspective and offer their knowledge.

Since FY2024, we have been using “Health and Safety Information Exchange Sessions” aimed at improving health and safety standards in the Meiden Group. This initiative invites employee to join tours of other companies inside the Meiden Group as a way of sharing successful examples of good health and safety activities with each base and related company in order to catalyze improvements within the Group. In the information exchange sessions, attendees confer and share opinions from each base and related company as a means of triggering increased motivation.

In November 2019, we built hands-on safety experience truck No. 2 for employees’ hands-on safety training, which we give at production sites (Numazu, Ota, Nagoya, and Kofu).

In 2023, we established the VR Safety Experience Training Evaluation System because we had been receiving many inquiries on the educational benefits of introducing VR safety experience training. The system features a storyline in VR that describes how accidents can be avoided by safe behavior. It also includes education to enhance understanding by providing feedback on behavior. Another characteristic of the system is that it visualizes the effectiveness of training by comparing against the results of previous training sessions.

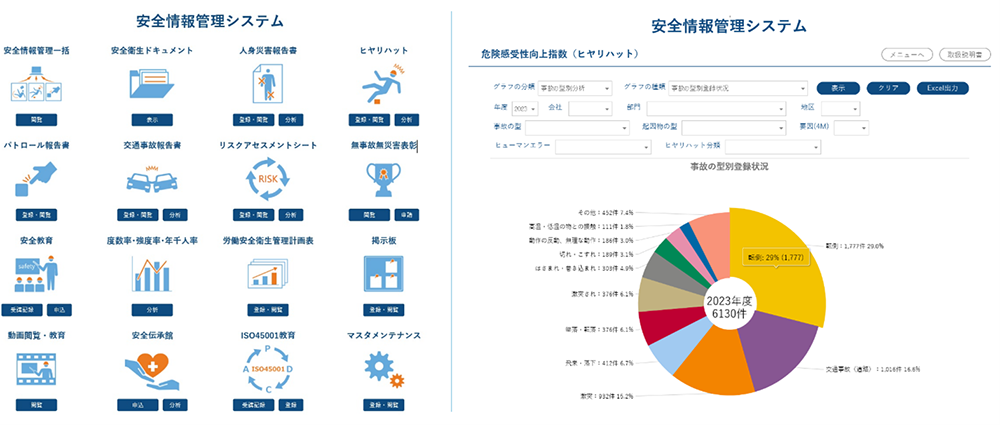

The Meiden Group started operating the Safety Information Management System in 2020. This tool effectively gathers and analyzes safety and health management information as it accumulates in the Group and uses it to improve health and safety management (with the PDCA cycle). The system can manage industrial accident reports, traffic accident reports, near-misses, safety patrols, risk assessments, number of days with zero accidents, safety training, safety indicators (accident frequency and severity rates, number of accidents per thousand persons each year), and more.

Using the system allows Group employees to easily access safety information and encourages their safety awareness and activities.

Immediately following an industrial accident, the entire company comes together and vows never to repeat the same mistake. This resolve, however, fades as time passes. In particular, when there is a change of managers in workplaces where an industrial accident has occurred, the lessons learned from the accident fade even more quickly.

In February 2020, we established the Safety Promotion Center as a place to encourage story-telling and thinking about industrial accidents that have occurred.

We believe it is our mission to never turn our eyes away from the sad facts and to keep telling our stories so that our employees and their families will never have to suffer tragedy again.

The Meiden Group strives to raise safety awareness and eliminate industrial accidents by training the body (with our hands-on safety experience trucks) and the mind (through the Safety Promotion Center).

In 2022, we developed the Metaverse Safety Promotion Center, a virtual reality experience that uses a head-mounted display. Then, in May 2025, we developed a laptop accessible Metaverse Safety Promotion Center that any Meiden Group employee can experience, aimed at reminding people of past incidents, improving employee safety awareness, and fostering a safety mentality. We believe that this will enable all employees to participate from their local factory, including overseas employees.

Finding unsafe behavior by on-site patrol is an important way to prevent industrial accidents, but in terms of resources, it is difficult to constantly check worker movements and images sent by cameras. To address this issue, in FY2023, we began using our Safety AI Camera System to check for all unsafe behaviors.

AI detects speed violations or driving in the opposite direction when operating a vehicle on premises, walking outside the green belt, not wearing a helmet in the factory, dangerous forklift operation, working at heights, presence of persons at night, and so on. It then provides guidance to those who are acting in an unsafe manner.