Sustainability - Supply Chain Management

The Meiden Group promotes sustainable procurement in conjunction with business partners, in order to contribute to the realization of a sustainable society.

Whilst the Corporate Code of Conduct is based on our Corporate Philosophy, we ask all of our business partners (suppliers) to conduct activities in accordance with our Basic Procurement Policy for CSR items that cover all of our business endeavors.

All of our procurement activities are based on the Meiden Group Corporate Code of Conduct.

The Meiden Group promotes enhanced supply chain management based on the basic policy of “Medium-term Management Plan 2027.”

We are working to conduct fair and impartial transactions, and to improve sustainability further while strengthening partnerships to help business partners understand the importance of promoting sustainability in the supply chain. Furthermore, we hope to promote legal compliance, environmental conservation, and community contribution activities, etc., with our business partners, with the aim of achieving mutual sustainable development.

We are strengthening our sustainability initiatives by building partnerships through actions like supporting the acquisition of environmental management system (EMS) certification for our business partners, providing follow-up education after EMS certification has been acquired, improving information security measures, supporting health and safety measures, and optimizing for mold management.

To ensure understanding of the Meiden Group’s approach to supply chain management in the context of material procurement, we give a copy of the Meiden Group Sustainable Procurement Guidelines to all suppliers and ask them to inform their employees and ensure compliance thereof.

When signing new contracts with suppliers, we ask them to comply with the Meiden Group Sustainable Procurement Guidelines. These cover human rights, labor, health and safety, the environment, fair trade and ethics (including prohibition of corruption and bribery), and other matters. We also directly ask them to comply with both the Meiden Group Basic Procurement Policy and the Meiden Group Sustainable Procurement Guidelines at the production plan explanatory meetings held each year at each of our production sites.

As of now, we have given copies of the Meiden Group Sustainable Procurement Guidelines to approximately 1,600 of our domestic suppliers.

The Meiden Group Sustainable Procurement Guidelines were drafted with reference to the Japan Electronics and Information Technology Industries Association (JEITA)’s Responsible Business Conduct Guidelines (March 2020 edition), and are now available in three languages (Japanese, English, and Chinese).

We have established a conflict minerals response policy, and the Meiden Group Sustainable Procurement Guidelines clearly express our intention to address the conflict minerals issue.

In order to fulfill its corporate social responsibility through procurement activities, the Meiden Group promotes initiatives to prevent the use of conflict minerals (tantalum, tin, gold, and tungsten) mined in the Democratic Republic of the Congo and surrounding nations, which are used to fund armed group activities that repeatedly engage in human trafficking, forced labor, child labor, abuse, etc., or inhumane acts, etc.

We conduct surveys of high-risk minerals as a due diligence measure, using the Conflict Minerals Reporting Template (CMRT) developed by the Responsible Minerals Initiative (RMI).

In FY2024, we surveyed approximately 420 major business partners, focusing on companies that did not respond to the previous fiscal year’s survey. We asked about the parts they purchased in the past year, and reached a response rate of 93%. If the surveys reveal that minerals have been used to support conflicts, we ask our business partners to take corrective action to avoid using the relevant minerals, such as by changing suppliers. Furthermore, if customers identify risky refineries, we ask business partners that use these refineries to re-examine the status of their business dealings. Additionally, in FY2023 we began a cobalt and mica survey using the Extended Minerals Reporting Template (EMRT).

At present, we have not confirmed any relationships between our business partners and armed groups, and we are conducting measures aimed at identifying refinery operators and ensuring supply chain transparency.

The Meiden Group considers ensuring a transparent supply chain and conducting responsible procurement of materials and parts to be important matters. We request that all of our business partners accept our Policy on Conflict Minerals Issue and cooperate with our initiatives to source conflict-free minerals.

Based on our corporate philosophy of “contribute to people, society, and the global environment to make a world a better place to live,” we are proceeding with environmental activities in accordance with the Meiden Group’s Environmental Action Policies. In material procurement, throughout the entire life-cycle to disposal, we try to make environmentally conscious products and reduce disposal, and engage activities in protecting the global environment by energy-saving, resource-saving, and minimizing the use of toxic chemicals, etc.

We view procurement of materials as part of our supply chain sustainability activities. We drafted the Green Procurement Guidelines to clarify our policies and request even greater understanding and cooperation from our business partners.

We provide the Green Procurement Guidelines to domestic business partners and we request all new business partners to disseminate and apply at the time of the first transaction.

Furthermore, by issuing sustainability surveys (environmental activities surveys), we are able to understand our business partners’ CSR promotion activities and environmental activities, conduct risk assessment, and receive assistance with our sustainable procurement activities, including green procurement.

In FY2022, we revised our Green Procurement Guidelines in light of the needs of the times. We engage with a broad range of environmental issues that businesses need to consider, such as reducing GHG emissions, using water effectively, and caring for biodiversity. We work with business partners to promote climate change countermeasures.

We ask our business partners to understand the importance of global environmental conservation activities and to cooperate in our activities. Please refer to the Green Procurement Guidelines (revised July 2022) for details.

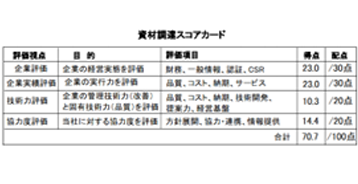

We convey the importance of sustainability and our philosophy to our business partners, including legal compliance, environmental protection, and community contribution, as listed in the Corporate Code of Conduct. In addition to evaluating business partners for quality, delivery, price, capacity for technological development, and environmental certifications, we look at whether they are fulfilling their social responsibility in terms of risks to the environment and social issues like human rights and labor, fair trade principles, social contribution, environmental conservation, and management of chemical substances.

Through this evaluation, we work to gain an understanding of business conditions relating to social issues such as climate change, biodiversity, environmental management, human rights, and working environments, and then to identify suppliers which have a high-risk. Also, when we start working with new suppliers, we conduct environmental audits on suppliers where there are high environmental risks. This way, we can assess and correct any risks.

We conduct appropriate, fair, and impartial procedures for all business partners through surveys relating to sustainability promotion and environmental conservation activities at the time of the first transaction. (FY2024 survey record: 1,615 companies)

Furthermore, we evaluate suppliers through “our business partners’ evaluation system” and issue a score card each year based on the results. (453 companies evaluated in FY2023. Not conducted in FY2024 due to revisions to the guidelines and SAQ)

In FY2024, we conducted a human rights due diligence survey for our primary business partners. (FY2024 results: 265 companies)

The purpose of the survey was to understand the state of human rights and labor initiatives at our business partners, relative to the Sustainability Procurement Guidelines and the Human Rights Policy used by Meiden Group. The aim is to then use this survey to contribute to the creation of a sustainable society.

Moving forward, the Meiden Group will continue to promote initiatives with our business partners that emphasize human rights.

When promoting environmentally conscious design, which forms part of our environmental management activities, we operate an environmental BOM* management system that is compliant with the regulations governing chemical substances in products.

In the Green Procurement Guidelines, the Meiden Group has stipulated two risk levels (prohibition and reduction) for hazardous substances regulated by laws and regulations relating to chemical substances such as the RoHS directive and REACH regulations. Based on this, we conduct surveys of chemical substances contained in procured materials and expand environmentally conscious products by promoting the elimination of hazardous substances.

We provide assistance not only for the Meiden Group but also for business partners, to build environmental management systems (EMS) and promote the reduction of environmental impact. We ask our partners to participate in these activities too, and promote the reduction of environmental impact throughout the entire supply chain.

We ask our business partners to create environmental management systems. In particular, we strongly recommend acquiring external EMS certification such as ISO14001 and EcoAction 21.

We conduct environmental audits on suppliers. While checking circumstances on the ground, we confirm and provide guidance on compliance with laws and regulations regarding chemical substances, waste, and the like. Suppliers who did not pass the audit were asked to take corrective measures and given a follow-up audit (9 companies).

If suppliers do not yet have an environmental management system (EMS), we have them take part in an EcoAction 21 study session (Green Program).

The Meiden Group is providing support for the environmental management system, EcoAction 21 certification, promoted by the Ministry of the Environment, and registration activities of our business partners, and aim to spread environmental management systems and environmental improvements throughout the entire value chain. We promote green procurement, giving priority to the purchase of products and parts from environmentally conscious suppliers. We also promote efforts to reduce GHG emissions and pursue carbon neutrality. As of FY2024, the tenth year of the program, a total of 145suppliers (8 more than FY2023) have earned EcoAction 21 certification.

Also, in FY2024, we held explanatory sessions in Shizuoka, the Kanto area, and online, with nine new companies joining EcoAction 21 study sessions (Greening program, municipal initiatives program). Additionally, since FY2023, we have been working with the Organization for Small & Medium Enterprises and Regional Innovation, Japan to visualize our suppliers’ CO₂ emissions.

We will continue providing support for our business partners in relation to EcoAction 21 certification and registration activities, and aim to promote environmental management systems, environmental improvements, and CO2 emissions reductions throughout the entire value chain.

With the support of the Organization for Small & Medium Enterprises and Regional Innovation, Japan, Meidensha is supporting the acquisition of Business Continuity Planning (Jigyokei) certification for small- and medium-sized businesses. METI offers this certification program to provide SMEs with swift and effective responses to disasters and emergency situations so that they can strengthen their business continuity. Participating in this program and obtaining Business Continuity Planning (Jigyokei) certification contributes to the speedy resumption of business when a business partner experiences disaster.

In FY2024, we held two Business seminars with the Organization for Small & Medium Enterprises and Regional Innovation, Japan (59 employees from 49 companies participated).

Meidensha will continue to conduct activities that support ongoing Jigyokei certification. These actions will support and promote fortifying our business partners’ BCP with the goal of being a society that can stably manage operations during disasters.

We report good examples of EcoAction 21 initiatives to suppliers at regional production plan briefings.

At the case study presentations, we explain the efforts of the example companies to visualize their issues and establish systems to address issues with small groups through EcoAction 21 activities, and the outcomes of their efforts, namely reducing energy and chemical usage. These presentations are motivating for the example companies because they are opportunities for participating companies to learn about their successful efforts.

We lend the necessary molds for manufacturing products to our suppliers and develop consensus on the handling of molds (returns, disposal, compensated storage) through discussions with all relevant suppliers (311 companies) so that unfair or unoptimized management costs to store those molds do not put undue pressure on their operations. As we continue to establish consensus with our suppliers each year on borrowing molds, we conduct retroactive payments for the storage cost associated with borrowing molds.

We will continue to optimize mold management.

The Meiden Group is conducting the following activities to build relationships with business partners.

We are directly confirming the challenges and requirements of our partners and pursuing support activities.

Business Partners are regularly visited by officers of Meidensha, the head of the Procurement Group, and production engineering staff, who gather information such as issues and requirements, which leads to improved functionality, quality, and productivity.

The Meidensha website has introduced “instructions for initial transactions” and “transaction application form” on material procurement, and we collect information on a broad range of business partners.

We regularly post information about subsidies (grants, etc.) for SMEs on our supplier portal (web), and supply information so that opportunities to update equipment, etc., are not missed.

We also contribute to the business efficiency of our business partners by creating efficiency in operations from submission of quotations to ordering, ATP, and delivery, using paperless electronic information, conducting conflict minerals surveys using a questionnaire, and confirmation of BCP implementation and damage caused by earthquakes and typhoons, etc.

Meidensha has established the Public Whistleblower Hotline : contact person is an outside lawyer (Law Office Hironaka), for the officers and employees of our business partners, in order to promote appropriate dealings. We request our business partners to report or consult with this contact point when they discover any violation of laws and regulations, inappropriate behavior, or potential violation of laws and regulations by our employees in relation to business transactions.

Details on the management of information, protection of reporter confidentiality, response to reports, etc., can be found on the Procurement Group webpage. (Only in Japanese).

We aim to build sustainable relationships with our business partners, and work to increase engagement with business partners with the basic philosophy of collaboration and co-creation. We believe that it is important to appropriately understand and respond to demands and expectations of the Meiden Group.

We host Meidensha Partners Meetings to enhance two-way communication with business partners and strengthen relationships. The President gives messages to business partners concerning future Meidensha policies, and awards to praise the assistance and contribution towards business activities and production activities. He appreciates them face-to-face, and rewards exceptional activities and results. Additionally, the President visited the award-winning business partners to express his gratitude to all their employees.

Each year, we invite our major business partners to each production site in order to directly share information, inform, exchange opinions, and communicate with our business partners.

We hold seminars on process improvement and information security measures at our suppliers' manufacturing sites as needed to improve their capabilities. We hold product exchange meetings with workplaces, where we communicate and exchange opinions with workers. In collaboration with the Corporate DX Promotion Group, we conducted on-site checks of whether appropriate information security measures were being taken to prevent information leaks and provided advice. Also, in terms of health and safety, we have commenced workplace checks of our business partners using the Health and Safety Support Project. In order to raise the awareness and efforts of our business partners regarding social responsibility, we actively provide training and support for environmental, health and safety, information security, and BCP measures, as well as sharing best practices.

In order for the member of Procurement Group to behave in a proper manner, we have devised “absolute compliance matters” and “absolute prohibitions” as a code of conduct for the Procurement Group so that all employees reflect on their own actions and do not commit any inappropriate conduct.

We read the following items at every morning meeting and ensure that all employees know them as a daily education; legal compliance, prevention of corruption, respect for human rights, labor practices, consideration for the environment, quality, safety, and information security, etc.

The whole Meiden Group is working to enhance procurement systems. Monthly meetings are held with the procurement divisions of major group companies to promote initiatives for improving the procurement base and to share information.

The Procurement Group has participated in the Supply Chain Subcommittee since FY2024. In collaboration with other participating companies, we are working to improve sustainable procurement in our supply chain.

A Declaration of Partnership Building is a declaration by company representatives to seek coexistence and co-prosperity throughout supply chains, build new partnerships, and adhere to desirable business practices, all with the aim of creating sustainable relationships in which large and small companies can grow together.

In our declaration, we expressly identified the following individual items: