Sustainability - Environmental Impact Data (FY2024) From the Four Main Manufacturing Sites (Domestic Manufacturing Sites)

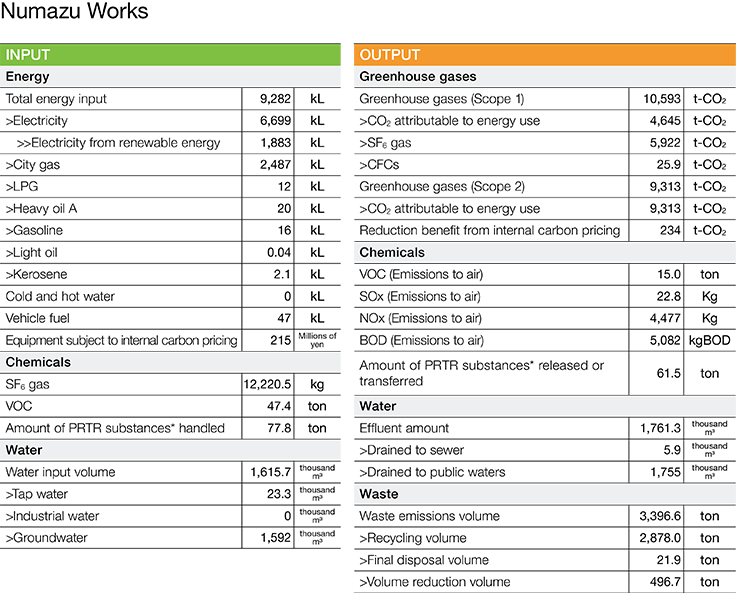

The Numazu Works is the main factory of the Meiden Group and conducts development, design, and manufacture of supervisory control equipment, power conversion equipment, power transformers and distribution panels, motor control equipment(inverters), electronic products, and surge arresters, development of software for integrated control devices and standalone, and on-site installation, and after-sales service for products.

At Numazu Works, in addition to promoting efficient energy use through capital investments and improvements to equipment operation, we began procuring electricity from CO2-free sources in July 2023 and are working towards the goal of 100% CO2-free energy by FY2027. Additionally, to avoid the risk of wastewater discharge, we began a complete upgrade of our wastewater system in FY2022 and are targeting FY2026 for completion of the plant’s wastewater system.

Numazu Works, Environmental Manager, Masanori Fukumoto

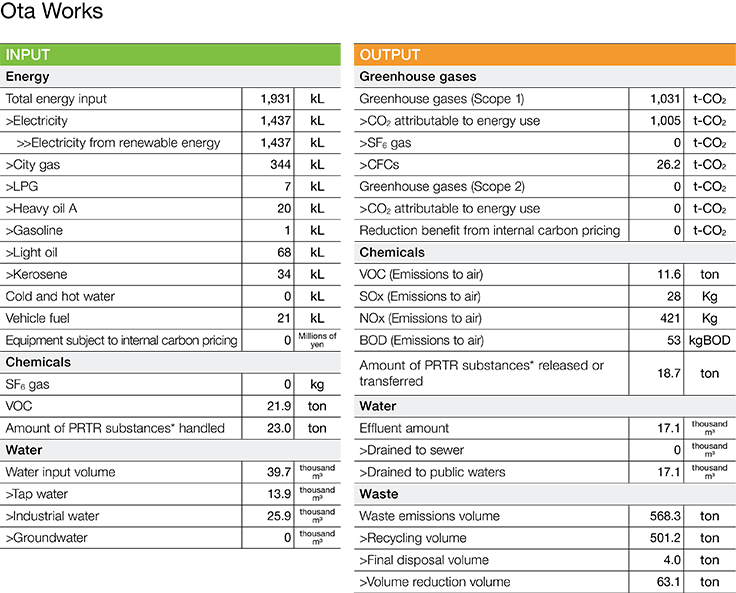

The Ota Works conducts development and manufacture of large electric generators, power generation equipment, dynamometer systems, and control equipment, etc.

In addition to previous environmental activities, this year, we procured CO2-free electricity and achieved zero greenhouse gas emissions from electricity consumption. We will continue working to reduce our environmental impact and achieve the SDGs.

Ota Works, Environmental Manager, Manabu Fujikawa

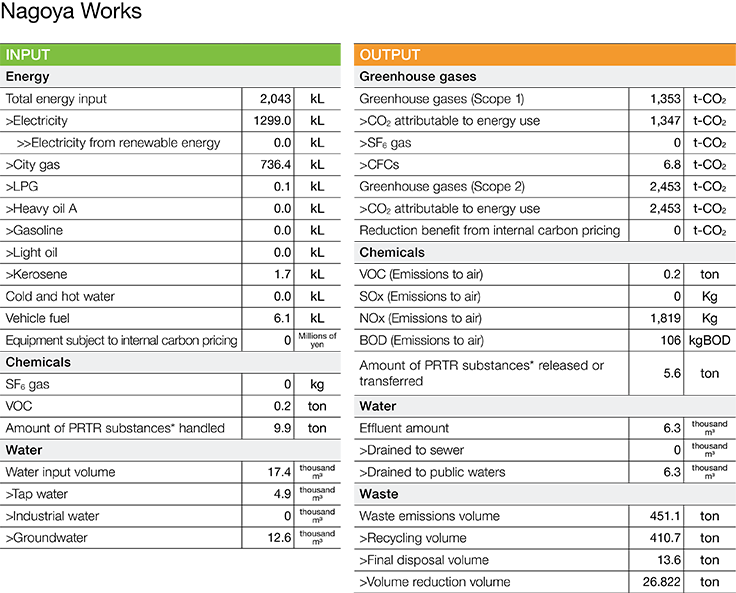

Nagoya Works develops and manufactures logistics and transportation products, ceramic flatsheet membranes used in water treatment, and other such products, and has also been manufacturing integrated motor/inverter equipment for EVs since FY2020. In FY2024, we began developing and manufacturing ceramic inserts for use primarily in public works projects, and also began research and development into areas involving high-concentration ozone gas as well as the application and development of ceramic flatsheet membranes.

In FY2024, production of integrated motors for EVs and ceramic flatsheet membranes decreased, resulting in lower emissions of greenhouse gases, but we built on that by operating equipment efficiently and are aiming for further improvements in emissions per unit of production.

And, in FY2025, we will switch all on-site equipment to CO2-free energy.

As the rate of decarbonization increases and technology for the electrification, computerization, and artificial intelligence of vehicles evolves rapidly, Nagoya Works will continue to focus on using electrification to contribute to society.

Nagoya Works, Environmental Manager, Tomohisa Asakura

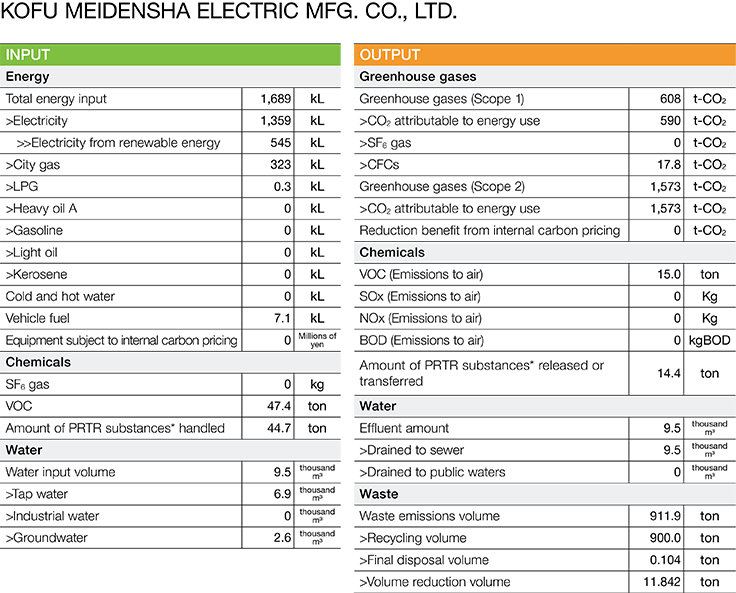

Since its foundation in 1943, KOFU MEIDENSHA ELECTRIC MFG. CO., LTD. has been manufacturing small and medium-capacity industrial motors and forklift motors, and has been manufacturing EV motors since 2009.

In FY2024, we advanced material recycling by sorting plastic waste (burnable waste) from the waste generated in the manufacturing process, reduced our environmental burden from waste generation, and reduced costs in processing. Each worksite strives to eliminate wasteful energy practices and improve emissions per unit of production. Also, in FY2024, we procured 44% of the energy we used from CO2-free energy as we work to reduce greenhouse gas emissions. In FY2025, we will switch all on-site equipment to CO2-free energy.

KOFU MEIDENSHA, Environmental Manager, Oda Shigehiro