Sustainability - Prevention of Pollution and Effective Utilization of Resources

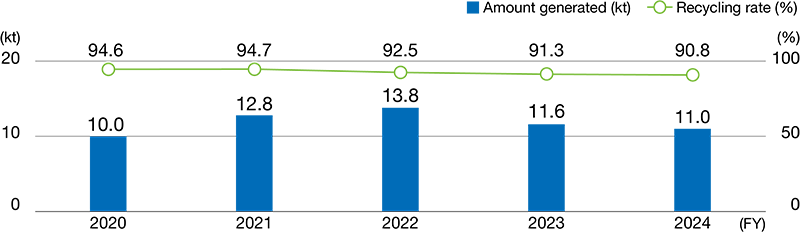

The Meiden Group is working to reduce the environmental impact of our domestic and overseas business activities, as well as reduce and properly manage hazardous substances, promote recycling of waste materials, and conserve water resources as stipulated in the President’s Environmental Policy. Furthermore, we will take steps to maintain a recycling rate of roughly 90% in line with the target in our voluntary action plan for the electrical and electronics industry.

The Meiden Group set targets to reduce the environmental impact of our products, services, and business activities, namely reducing the total volume of waste (1% YoY),*1 maintaining a recycling rate of roughly 90%,*2 and reaching a final disposal rate of 1% or less.*2 Going forward, we will continue striving to promote recycling by promoting environmentally friendly design, product parts, and materials as well as the 3Rs of business-related waste.

As a manufacturer that uses resources to provide our products and services, it is essential that we use those resources effectively.

At the Meiden Group, we practice eco-friendly procurement and work to mitigate the environmental impact of our domestic and overseas business activities and to design products that conserve and reuse resources.

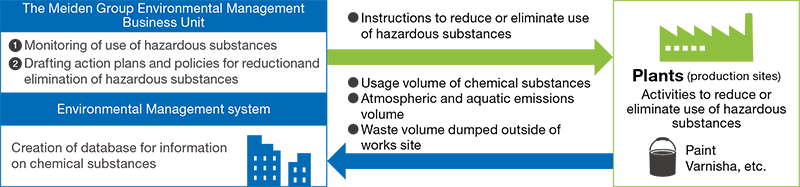

We are working to conduct risk assessment of chemical substances used at production sites, etc., to improve the workplace environment, and reduce or substitute hazardous chemical substances with a substantial risk.

In order to prevent workplace accidents, health impairment, and fire or environmental pollution due to leakage or spillage of chemical substances, we routinely conduct patrols of sites where chemical substances are used to alert workers, and take corrective measures where the management status of chemical substances is found to be inappropriate.

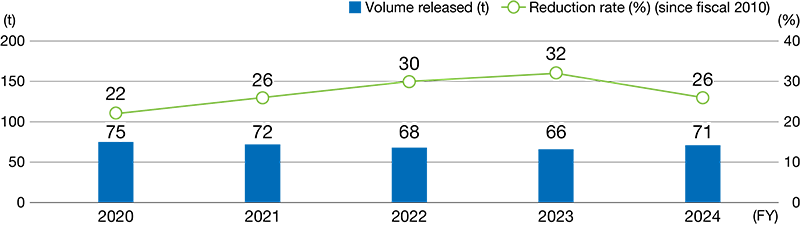

In FY2024, our reduction rate fell due to increased production, but we continued our replacement with low-VOC solvents, and released 71.2 tons of VOC, an increase of only 5 tons versus the previous fiscal year. Going forward, we will promote reduction of VOCs released through adoption of styrene-free varnishes, substitution with low VOC paint and solvents, introduction of airless spraying, and more.

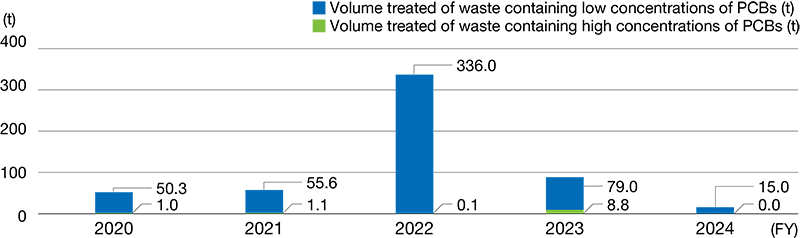

In accordance with the Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes (PCB Special Measures Act), we are gradually disposing of devices that contain PCBs (polychlorinated biphenyls) such as transformers and condensers that were manufactured in the past and stored for nearly to 40 years.

In FY2024, we disposed of no waste containing high concentrations of PCBs*1 and treated 15.0 tons of waste containing trace amounts*2.

Since we began processing PCB waste in FY2007, through FY2024 we have disposed of approximately 114 tons of waste containing high concentrations of PCBs and treated about 828 tons of waste containing trace amounts.

Going forward, we will continue to work to comply with laws and treat PCB waste by the treatment deadline.

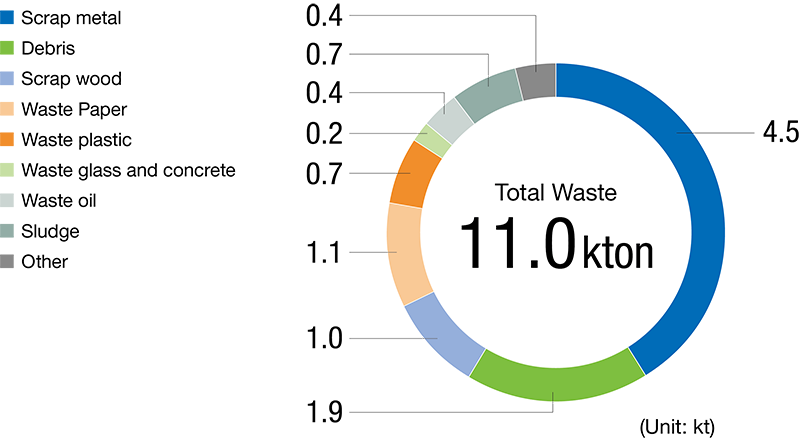

Meidensha is working to recycle waste generated at production sites and offices.

In FY2024, although there was an increase in the amount of metal waste generated following the retirement of a model in the EV business, advancement of the 3Rs at other production sites was able to control the amount of discharge and so the total amount of waste generated fell slightly compared to the previous fiscal year. Going forward, we will continue to work to reduce the amount of waste generated and improve the recycling rate by continuing to promote the 3Rs.

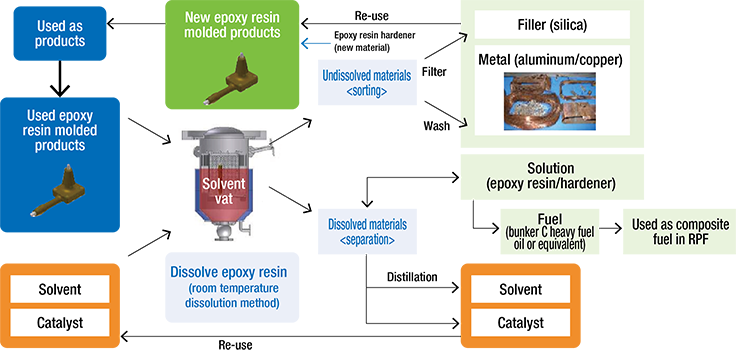

Meiden Chemical Co., Ltd., which is a group company involved with manufacture and sale of electrical insulators has realized the recycling of used epoxy resin molded components as raw materials by using a method of depolymerization under ordinary pressure, which separates the metal from the resin. Epoxy resin molded components are generally disposed of in landfill as they are considered difficult to recycle; however, Meiden Chemical Co., Ltd. has licensed the patented room temperature dissolution method from Showa Denko Materials Co., Ltd. (formerly Hitachi Chemical Co., Ltd.), which enables it to recycle 95% of existing components, as well as control cost than sending them to landfill. During recycling, we conduct lifecycle assessment (LCA) according to data obtained at the testing plant, which quantitatively assesses environmental impact if recycled and if not recycled.

In addition to insulating molded components, Meiden Chemical Co., Ltd. is working to roll out insulating material products as major flagships with features such as long-life resin for impregnation and environmentally friendly low-odor varnish.

Meiden Chemical Co., Ltd. is currently engaging in research such as extraction of rare metals by dissolving insulating varnish from superconducting coils and recycling of fiber-reinforced plastic to produce resources again.

In October 2023, we launched the “Bottle to Bottle” initiative in collaboration with Coca-Cola Bottlers Japan Inc., Asahi Soft Drinks Co., Ltd., and National Vending Co., Ltd. to recycle used PET bottles from our head office and R&D Center into new PET bottles, and introduced the initiative to Numazu works in June 2024. The initiative is the first in Japan for which Coca-Cola Bottlers Japan and Asahi Soft Drinks are collaborating with an electronics manufacturer on horizontal PET bottle recycling.

Bottle to Bottle is a recycling system in which used PET bottles are collected, recycled, and reused repeatedly as PET bottles.

Used PET bottles from our head office and R&D Center are still collected by cleaning companies and beverage manufacturers and recycled into various products, but we have never been able to determine what they were ultimately recycled into. Under this new scheme, 100% will be recycled into beverage product containers in the future.

This should enable us to recycle more than 9 tons of used PET bottles annually, leading to a roughly 60% reduction of CO2 emissions compared with the same amount of PET bottles manufactured using new fossil-based raw materials.

We will continue to promote recycling activities within the Meiden Group.