Sustainability - Water Resources

The Meiden Group will work on implementing measures to promote water resource conservation activities by utilizing water resources efficiently and respond to water risk that impacts business activities, as a step toward conservation of the global environment and realization of a sustainable society.

We will contribute to the solution of a range of social issues relating to the conservation of water resources through our businesses.

The Meiden Group includes “promotion of water reuse” and “water safety” as part of the medium- to long-term “Environmental Vision.” We will work to preserve water resources through water conservation and effective utilization of rainwater; take steps to respond to water risks such as water shortages, flood, and contamination; and improve sanitation. In FY2024 we established water withdrawal reduction targets for four major factories in Japan (Numazu, Ota, Nagoya, Kofu) and developed initiatives to reduce water withdrawal.

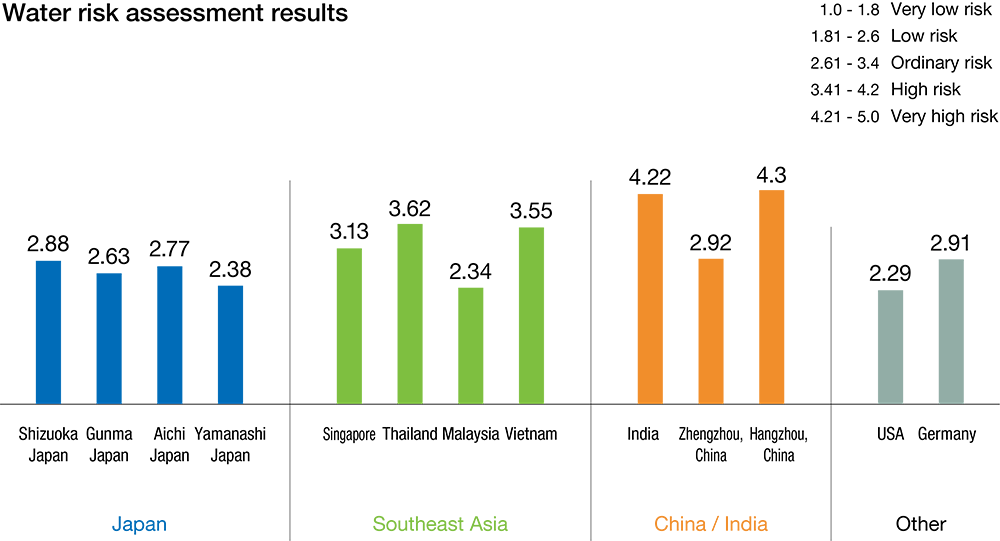

The Meiden Group conducts evaluation of water risk for initiatives to conserve water and comply with effluent standards. Using the Water Risk Filter, a water risk assessment tool distributed by the World Wide Fund for Nature, we assessed 14 production sites in 9 countries. We found that although domestic sites were within ordinary risk levels, more than half of overseas sites were located in high-risk areas. In particular, risks related to water quantity and quality assurance were found to be high. Some sites in India (Andhra Pradesh) and China (Zhengzhou) were found to be located in very high-risk areas. For these, we will take the optimal measures for each site based on assessment results.

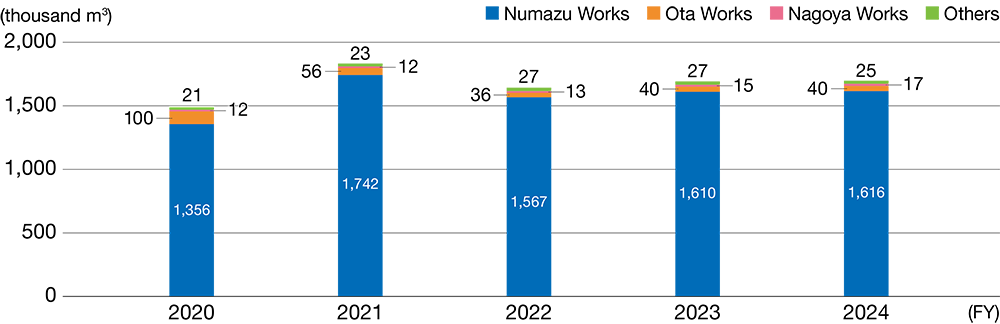

Water Withdrawals, by Production Site (Japan)

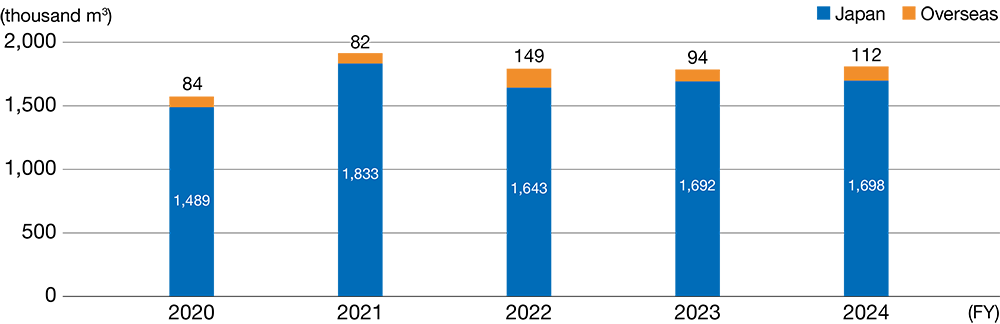

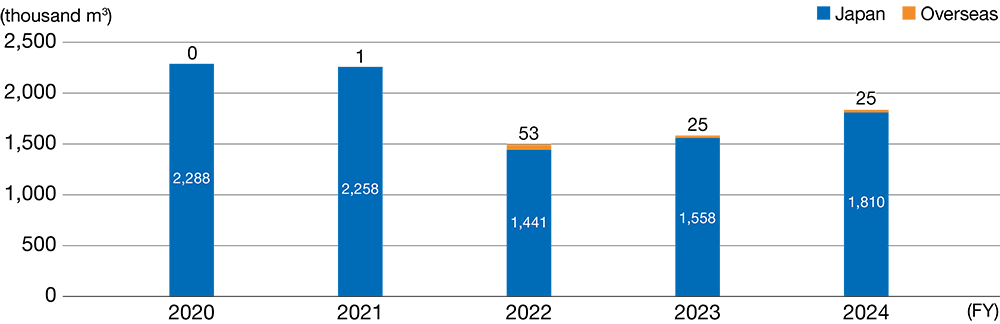

Water Withdrawals, by Region (Japan / Overseas) (Consolidated Group)

We ensure legal compliance by establishing and applying at each site and subsidiary voluntary standards that are stricter than legal restrictions.

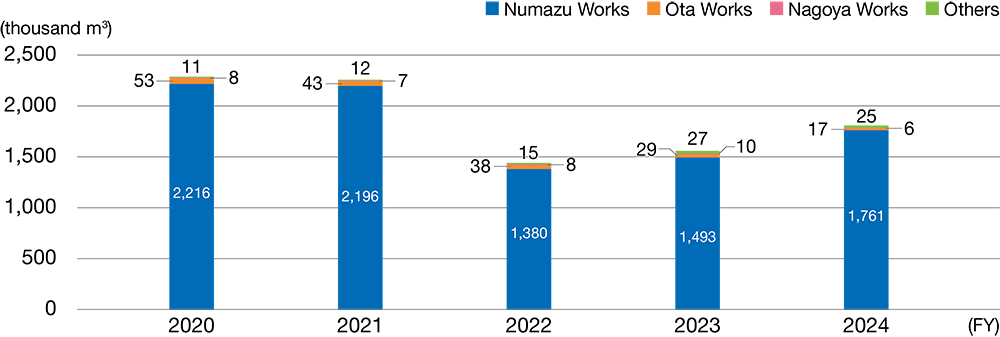

Volume Discharged, by Production Site (Japan)

Effluent Volume, by Regions (Japan / Overseas) (Consolidated Group)

Every year, the Meiden Group asks a third party to verify environmental data for the amount of water we withdraw and discharge.

On August 29, 2024, the Japan Audit and Certification Organization for Environment and Quality (JACO) completed their third party verification for FY2023, finding that in Japan, we withdrew 1,692,000 m3 of water and discharged 1,559 m3 of effluent.

More than 125 years have passed since the Meiden Group’s founding, and the infrastructure facilities at our Japanese production sites have aged noticeably.

This is particularly true of the water infrastructure, which we are rebuilding as a special priority for BCP reasons.

At Numazu Works, one of our main production sites in Japan, we began construction of a new large integrated water-purification tank in 2024, which is scheduled to go into operation in April 2026. We also plan to bring water supply pipes above ground starting in 2026. We are also currently reviewing constructing new integrated purification tanks in 2026 for Nagoya Works, another major Japanese production site. Ota Works is likewise aging and updates will be planned and implemented for this site as well.

[Overview of Project to Rebuild Water Infrastructure]

In addition to design, construction, and execution of water treatment plants, the Meiden Group provides total support through to operation and maintenance as a general water treatment manufacturer, based on our record of involvement with construction and development of water and sewerage systems in Japan. We are contributing to the solution of a range of issues relating to the conservation of water resources through or water infrastructure systems business, which is one of our core businesses.

MEIDEN SINGAPORE PTE. LTD. (MEIDEN SINGAPORE) has received an order from Singapore enterprise Koh Brothers Building & Civil Engineering Contractor (Pte.) Ltd. for ceramic flatsheet membranes for an industrial effluent MBR* facility at the Tuas Water Reclamation Plant of the Singapore Public Utilities Board (PUB). This project is a new water reclamation plant to be built in western Singapore, scheduled for completion in 2025.

MEIDEN SINGAPORE will supply ceramic flatsheet membranes with a treatment capacity of 97,500 m3/day to the plant. The Meidensha ceramic flatsheet membranes to be delivered can help to save energy and will offer high durability, excellent chemical resistance, and long life.

Under a 2010 memorandum of understanding (MOU) with PUB for the joint development of water treatment technology, we have been conducting a demonstration study on industrial effluent treatment at the Jurong Water Reclamation Plant. In 2014, a 4,550 m3/day demonstration plant began operating at the Jurong site. Highly concentrated industrial effluent that had previously been difficult to reclaim was successfully reused. PUB made note of the achievements, which led to the recent order for ceramic flatsheet membranes for the Tuas Water Reclamation Plant.

uas Water Reclamation Plant

Overseas subsidiary Meiden Singapore Pte. Ltd. (Meiden Singapore) has taken an order from a Singaporean company to supply ceramic flatsheet membranes for the Chestnut Avenue Waterworks of the Singapore Public Utilities Board (PUB). The order is for ceramic flatsheet membranes with a treatment capacity of 291,200 m3/day. The project is to replace the existing water purification system, which uses organic membranes, and is to be completed in 2026.

Meidensha ceramic flatsheet membranes to be supplied for the project will be housed in existing water tanks. This takes advantage of the characteristics of immersed-type membranes and minimizes installation costs. In addition, ceramic flat-sheet membranes offer excellent product durability, longevity, and energy efficiency. This makes them a highly economical choice, as they offer, for example, lower running costs (maintenance and membrane replacement costs) compared to the existing organic membranes.

Singapore, where water supply stability is a national concern, is a core base for Meidensha’s ceramic flat-sheet membrane business. As such, Meidensha has conducted demonstration research at various water treatment plants in Singapore. In addition to our continued assistance in securing water resources and a stable supply of water, Meidensha also seeks to contribute to the Global Hydrohub initiative of Singapore’s government.

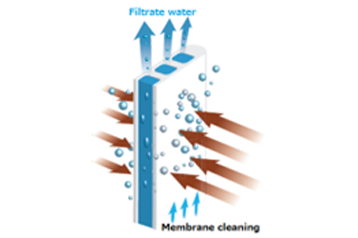

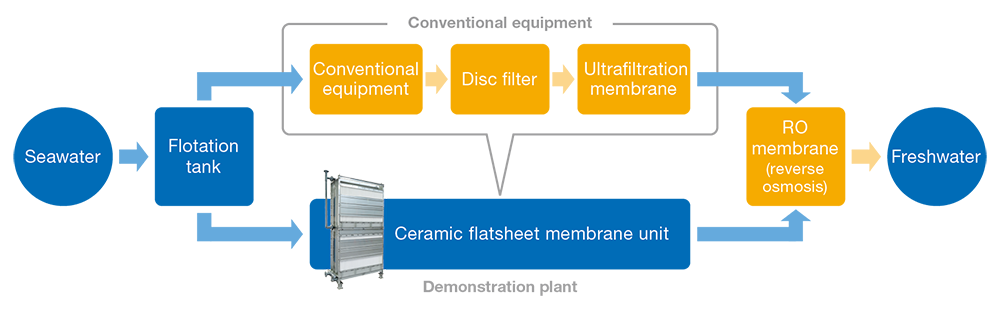

Overseas subsidiary Meiden Singapore Pte. Ltd. is constructing a pretreatment demonstration plant using ceramic flatsheet membranes at the Singapore Public Utilities Board’s (hereafter PUB) Tuas Desalination Plant.

Along with the implementation of energy reduction measures, this demonstration is expected to minimize equipment space compared to conventional facilities.

The Tuas Desalination Plant uses reverse osmosis membranes for desalinization. This demonstration plant makes use of ceramic flatsheet membranes in the impurity removal phase of the pretreatment process and is installed using existing pressurized-flotation equipment inside the Tuas Desalination Plant. (Processing capacity: approximately 32,000 m3/day)

Along with climate change, limited water resources is a global issue. The Meiden Group seeks to help solve water issues around the world so that water can be used sustainably. This is why we are developing our water infrastructure and ceramic flatsheet membrane businesses and actively investing in research and development.

Meidensha has been selected for the "B-DASH Project" led by the Ministry of Land, Infrastructure, Transport and Tourism, and is conducting a demonstration project that utilizes AI for wastewater treatment plant operation support technology. The MLIT’s National Institute for Land and Infrastructure Management (hereafter NILIM) contracted us to install AI-logic equipment to determine operation policies, lake conditions, and more, as well as AI-logic systems that centralize management of the various data from monitoring system equipment, the results of water quality analysis, and more in the Hiroshima Seibu Water Reclamation Center and the Funabashi Takase Sewage Treatment Plant. By applying AI to the operation management techniques of skilled technicians, the AI’s operational decisions for dissolved oxygen (DO) settings and polyaluminum chloride (PAC) injection settings matched more than 80% of those made by skilled technicians. Implementing AI operation diagnoses resulted in stable water processing volumes in line with the previous year. Also, in July 2025 the NILIM created guidelines for this technology and the government intends to expand it throughout Japan as innovative technology.

In 2005, we launched the TELEMOT Series as remote monitoring equipment for public infrastructure and have so far sold approximately 3,400 units as of last year. Last year we developed the TELEMOT MT2 as the successor of the TELEMOT MT and released it to market.

Both generations in the TELEMOT Series are highly compatible. As remote monitoring terminals using the cloud and remote monitoring equipment, regular updates to TELEMOT allow the series to be used from cloud and monitoring systems for many years to come.

TELEMOT MT2 also works in the most modern communication environments and can be deployed in large- and medium-scale facilities that could previously not incorporate conventional equipment, thanks to employing the most advanced telecommunication methods, vastly expanding input and output signal points, and implementing communication equipment with ADC Series (PLC).

We manufacture ceramic flatsheet membrane units geared for domestic and overseas water purification, wastewater processing, and effluent treatment that can be used in a wide array of fields, and in recent years have developed a new type of unit.

By directly connecting the ceramic flatsheet element with the water collection pipe for the membrane-filtered water, these units eliminate the hose used in conventional units, which allows for reductions in equipment floorspace and ongoing management costs.

We conducted a demonstration membrane filtration project using our new unit with actual river water as the water source and achieved stable operations with excellent membrane-filtered water quality, and so on March 18 2024 received technical certification for water filtration equipment from the Japan Water Research Center.

The Meiden Group, in cooperation with its stakeholders in Japan and overseas, will pursue manufacturing that contributes to resolving issues such as Sustainable Development Goal 6 (CLEAN WATER AND SANITATION) and Goal 14 (LIFE BELOW WATER), realizes sustainable value creation, and works to resolve social issues.

Through our participation in initiatives, Meidensha is promoting water resource conservation activities through the efficient use of water resources and measures against water risks that affect business activities.

CDP Water Security is an international NGO that operates a global disclosure system for corporate water risks. Meidensha has been participating by responding to the organization’s questionnaire since 2017.

We received a “B” rating from CDP Water Security in 2024.

In October 2024, Meidensha received the Water Cycle Active Business certification from the Cabinet Secretariat’s Office of Water Cycle Policy as recognition of being a business that actively contributes to the water cycle.

This certification system began in 2024 as a way to further encourage businesses to contribute to the water cycle and help increase recipients’ corporate value. Moving forward, we will continue to act as a business with a wide-ranging impact on the water cycle.